Crystallization Process for Margarine

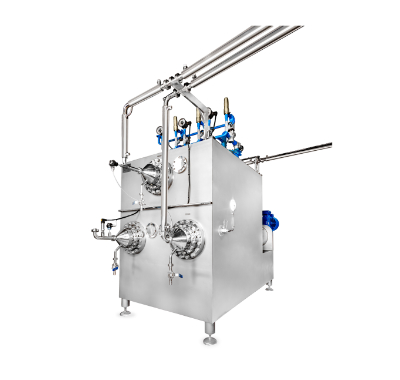

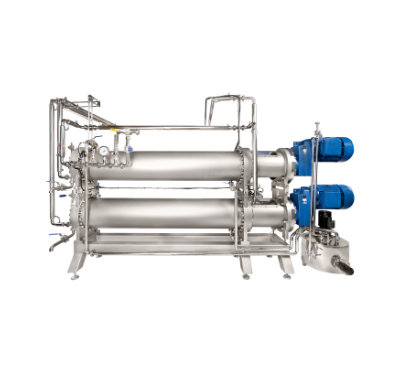

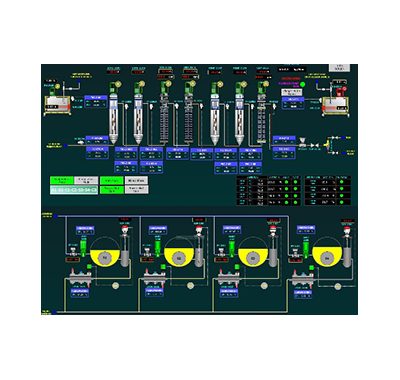

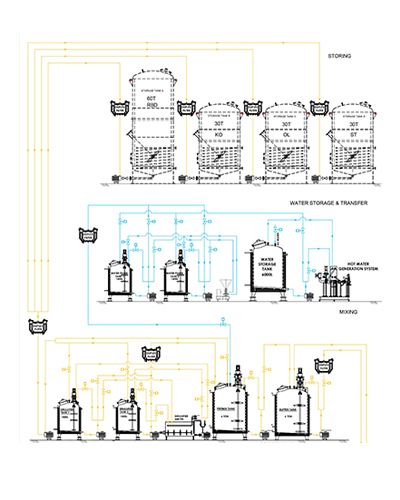

The Crystallization process for Shortenings and Margarines begins with the Pasteurization of the emulsion after which it is pumped into the Scraped Surface Heat Exchanger (SSHEs) with the help of a positive displacement pump. The emulsion is shock chilled in high pressure heat exchangers (SSHEs) with the help of continuous chilling and scarping action. Once chilled, the product is crystallized in three different stages. The first phase of crystallization is done with the help of the Crystallizer (Pin Rotors) in which the product is worked with the help of pins on both the rotating shaft and the body or Resting Tube with Sieve Plates. The final stage of crystallization takes place in the cold room or the warehouse for certain other over a maximum period of 48-72 hours.

Comments are closed.